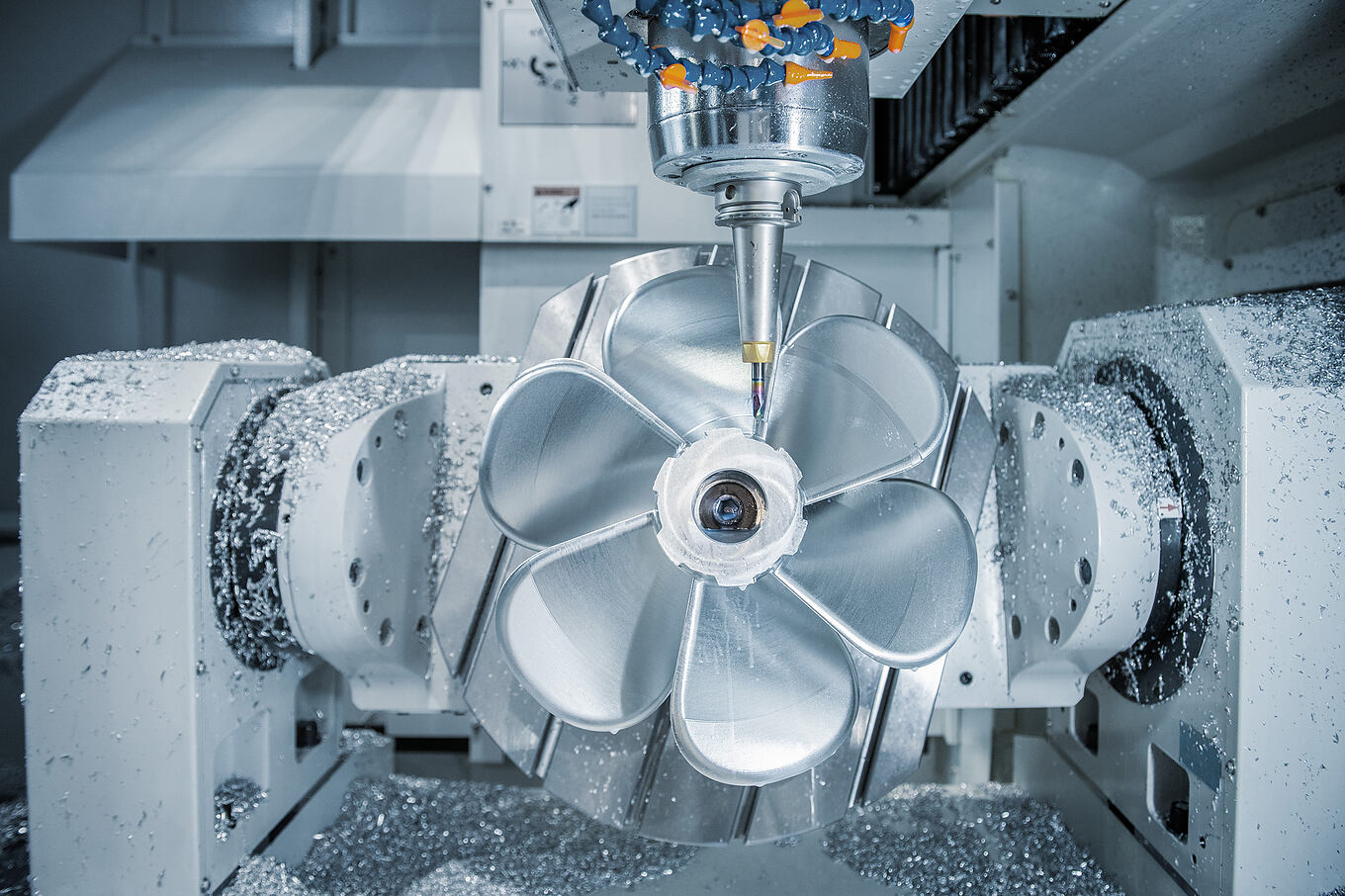

5-axis

precise

The U-series

Discover the complete range of 5-axis milling machines

.png)

.png)

The right 5-axis milling machine for any production

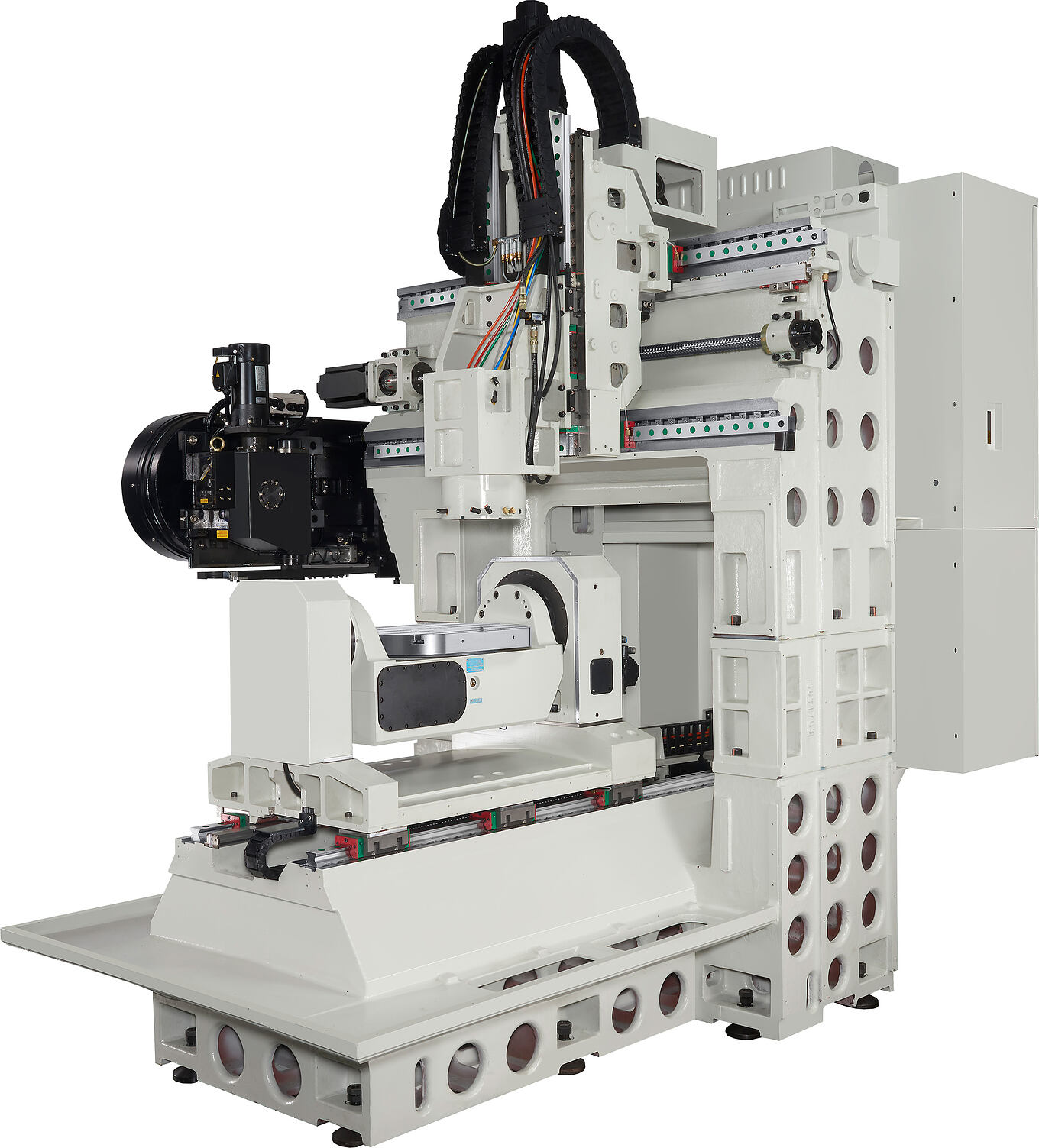

The compact cross table machining centers of the UC-series represent the perfect modestly priced entry into the world of high-precision processing with 5-axis machining centers. They offer optimal performance in machining small components. Even with their small footprint, these machines offer a large working area with a wide range of possibilities for the shop.

The compact U 400 and U 600 models are ideal for CNC machining of medium and small workpieces. The high rigidity of the U 800 is made possible by the gantry design and the stable machine construction made of cast iron.

For large and heavy workpieces with a maximum table load of 1,000 kg, the U 800 model with swivel bridge and the UB 3222 model with clevis are optimally equipped. At the same time, the gantry design enables high rigidity and low space requirements of the CNC-controlled machining centers. The A-axis of the U 800 machine is equipped with torque drive on both sides, the C-axis with torque drive.

Experience the highlights of the U-series

- Highly rigid and high-precision machine structure

- Long process runtimes due to thermal stability

- Spindle cooling for additional cutting performance

- User-friendly Heidenhain TNC 7 control system

- Heidenhain DCM integration for dynamic collision monitoring

- Optional additional equipment possible (e.g. touch probe for tool / workpiece measurement, automatic compensation of turning center lines for fast and uncomplicated precision adjustment by the user)

- Individually configurable according to your application needs

- Supported by fast service and high spare parts availability

Standard precision of the 5-axis machining center

Versatile and adaptable

We are happy to be there for you.

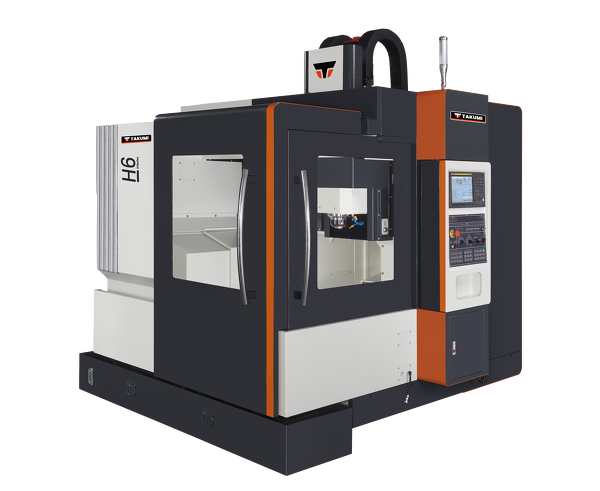

Discover our CNC high performance machining centers

3-axis vertical