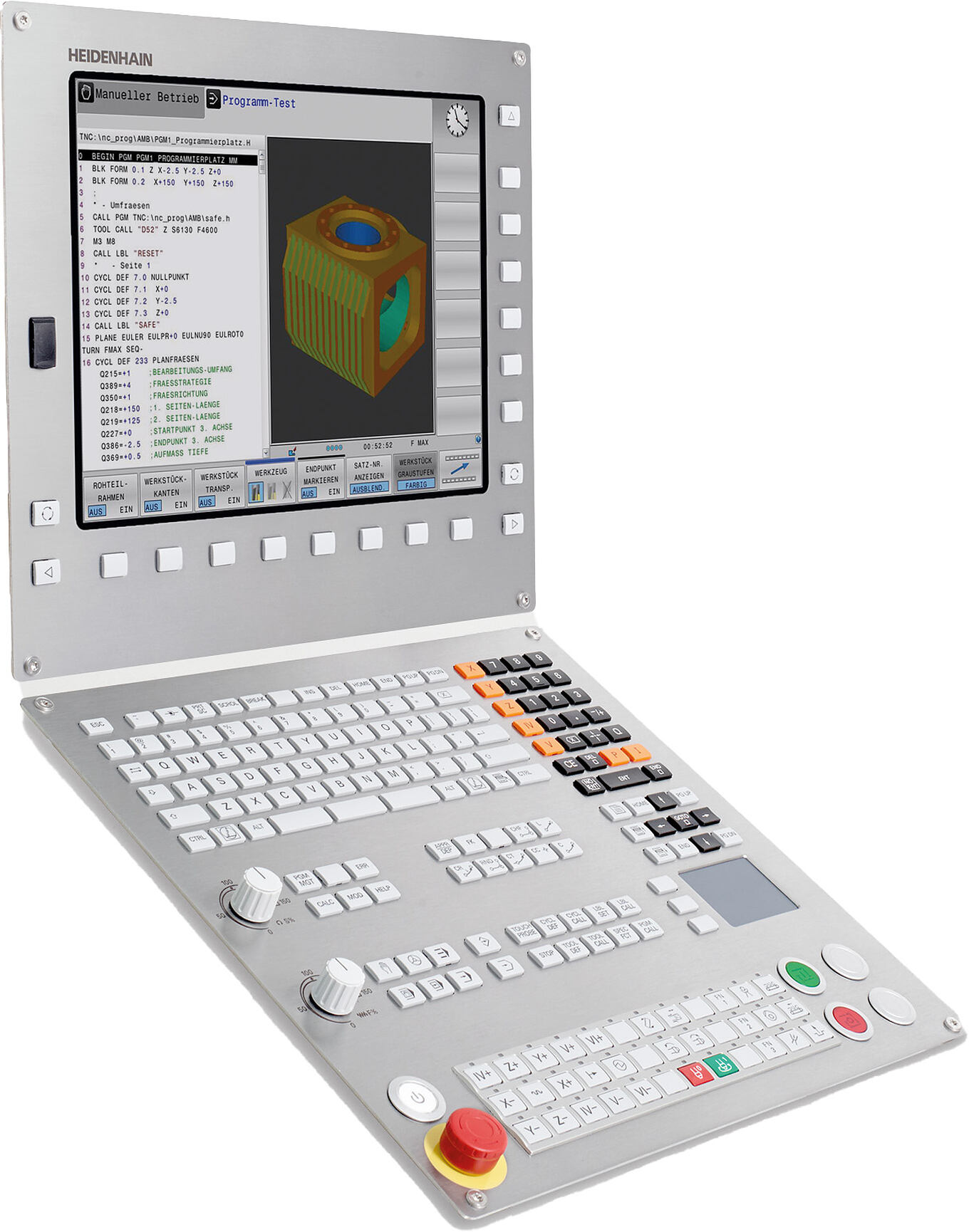

Our TAKUMI Machining Centers are equipped with the latest Heidenhain TNC control.

CNC-Maschines5-axis precise, U-Series

The precise space miracle

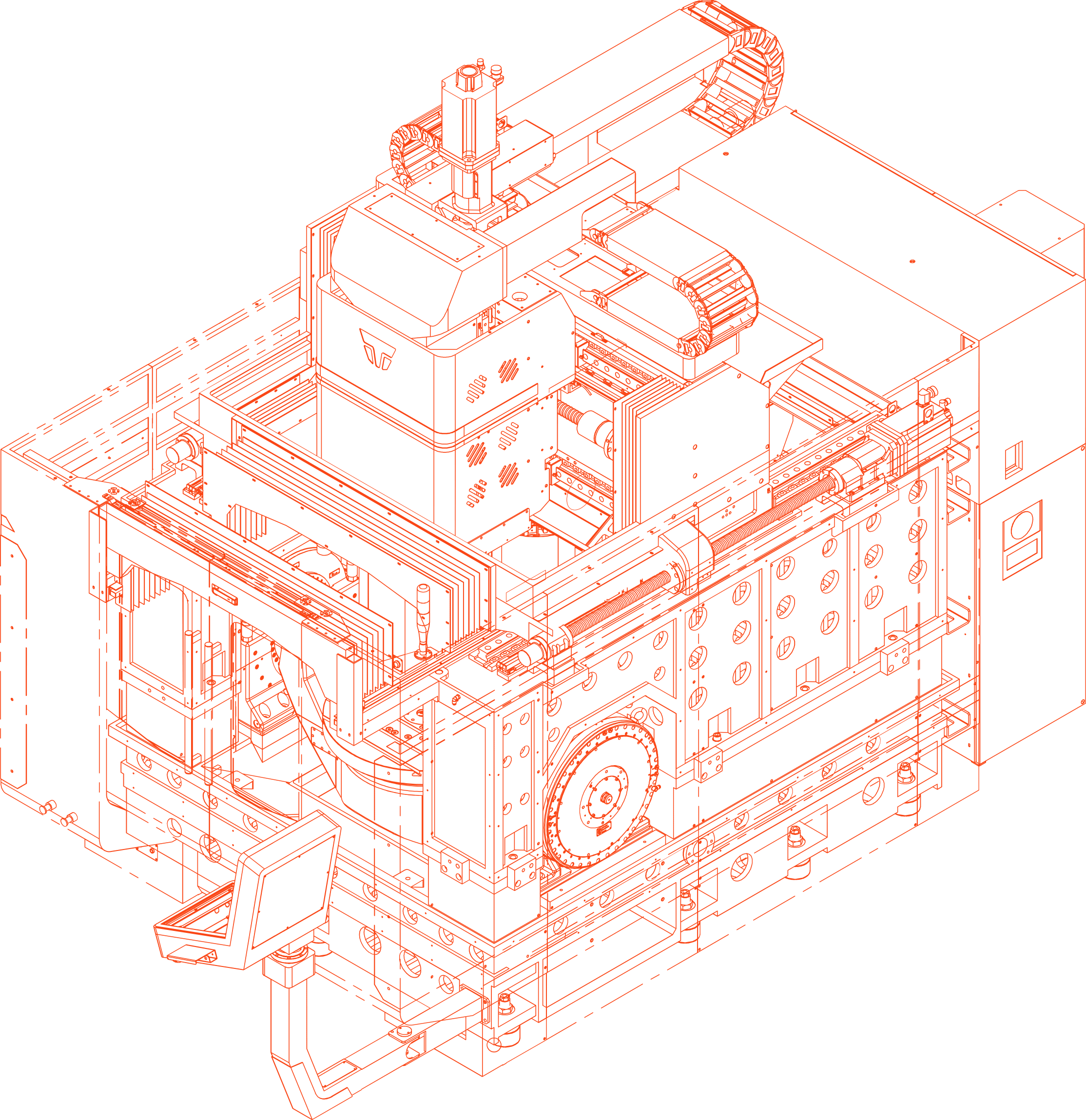

TAKUMI UC 320

The UC 320 is a space- and cost-saving entry into working with CNC milling machines. The compact, 5-axis simultaneous-capable cross table machining center with low space requirements and large working area is perfectly suited for machining small workpieces. It comes standard with everything you need for maximum precision, stability and a high surface quality - and can be adapted exactly to the requirements of your CNC production with optional accessories.

Travels and Table

X-Axis (mm): 440

Y-Axis (mm): 610

Z-Axis (mm): 520

Table working surface W x D (mm): Ø 320

Spindle Speed (rpm): 15.000

Produkt anfragen

Y-Axis (mm): 610

Z-Axis (mm): 520

Table working surface W x D (mm): Ø 320

Spindle Speed (rpm): 15.000

- Inline spindle with up to 15,000 rpm

- Preloaded recirculating ball screws in all axes against thermal deformation

- Spindle cooler

- User-friendly ergonomic loading and unloading through wide-opening machine doors

- Direct path measuring systems in all axes

- 5-axis simultaneous capability

- Optional: IKZ up to 70 bar (standard: 30 bar)

- Small footprint, large working area

Details

Specifications - UC 320

| Travels | |

|---|---|

| X-Axis (mm) | 440 |

| Y-Axis (mm) | 610 |

| Z-Axis (mm) | 520 |

| A-Axis (°) | +30 / -120 |

| C-Axis (°) | 360 |

| Table | |

|---|---|

| Table working surface W x D (mm) | Ø 320 |

| Load max. (uniform distribution) (kg) | 200 |

| Distance from spindle nose to table (mm) | 90 - 610 |

| T-Slots (DIN 650) | 4 x 12mm - 90° |

| Spindle | |

|---|---|

| Spindle Taper | SK40 - BigPlus / BBT40 |

| Type | In-Line |

| Power S1/S6 (kW) | 10 / 14 |

| Torque S1/S6 (Nm) | 63,7 / 89,4 |

| Spindle Speed (rpm) | 15.000 |

| Feed Rate | |

|---|---|

| Rapid Traverse X/Y/Z-Axis (m/min) | 36 / 36 / 24 |

| Cutting Feed Rate X/Y/Z-Axis (mm/min) | 12 |

| Rapid Traverse A/B/C-Axis (1/min) | 16,7 / - / 22,2 |

| Cutting Feed Rate A/B/C-Axis (1/min) | 16,7 / - / 22,2 |

| ATC & Magazine | |

|---|---|

| ATC Type | Doppelgreifer |

| Magazine Capacity | 40 |

| Maximum Tool Diameter (mm) full / next pocket empty | 75 |

| With Empty Pockets (mm) | 120 |

| Maximum Tool Length (mm) | 240 |

| Maximum Tool Weight (kg) | 7 |

| Space & System Requirements | |

|---|---|

| Maximum Floor Space (mm) W x L x H | 2.210 x 3.035 x 3.225 |

| Machine Net Weight (kg) | 5.720 |

| Electrical Power Consumption (kVA / A) | 75 |

| Air Requirements (bar) | 6 |

Spindle

Choose the spindle that suits you

| Spindle options | UC 320 | |

|---|---|---|

| Drehzahl max. (1/min) | 15.000 | 15.000 |

| Leistung S1/S6 (kW) | 10 / 14 | 10 / 14 |

| Drehmoment S1/S6 (Nm) | 63,7 / 89,4 | 63,7 / 89,4 |

| Schnittstelle | SK40BigPlus | BBT40 / HSK63-A |

| Standard / Optional | Standard | Optional |

Features

Always perfectly equipped

Great features of our standard equipment

- Heidenhain TNC 640 control system

- Direct-drive spindle 15,000 rpm HSK-A63 / SK 40

- Cooling system with cooling ring

- Linear scale measurement systems on all axes

- Thermal-expansion compensation system for spindle

- Internal coolant feed through the spindle (ICF 30 bar)

- Chip flushing

- Spindle cooler

- Working area illumination

- Oil skimmer

- Rinsing and compressed air gun

- Scraper-type chip conveyor and chip trolley

- Ethernet interface

With further optional equipment you can adapt the TAKUMI UC 320 to your needs

- Heidenhain TNC 7 control system

- Touch probe system for workpiece measurement

- Touch probe system for tool measurement

- Programmable external cooling air

- Programmable cooling air through the spindle

- Oil mist separator

- Knoll production package

- Bypass filtration system

- Rotoclear

Highlights

Heidenhain Control TNC 640

Precise High performance spindle

- With the U-Series TAKUMI offers the optimal spindle for your demands

- Spindle speeds from 12.000 to 15.000 (rpm)

- Output up to 10kW – 30kW

- Interface: HSK63-A / SK40 - BigPlus / BBT40 / HSK100-A

Extremely stiff and high-presision mechanical structure

- The load-bearing mechanical structures such as bed, pillar, bed sledge are made of heat-treated and stress-released Meehanite cast iron. The thereby gained absorption capacity enables low-vibration machining processes. This ensures high surface quality on the workpiece and increases the tool life.

- Portal construction and stepped column for maximum rigidity, optimized force flow, minimization of the spindle overhang and increased dynamics

- Three-plybed