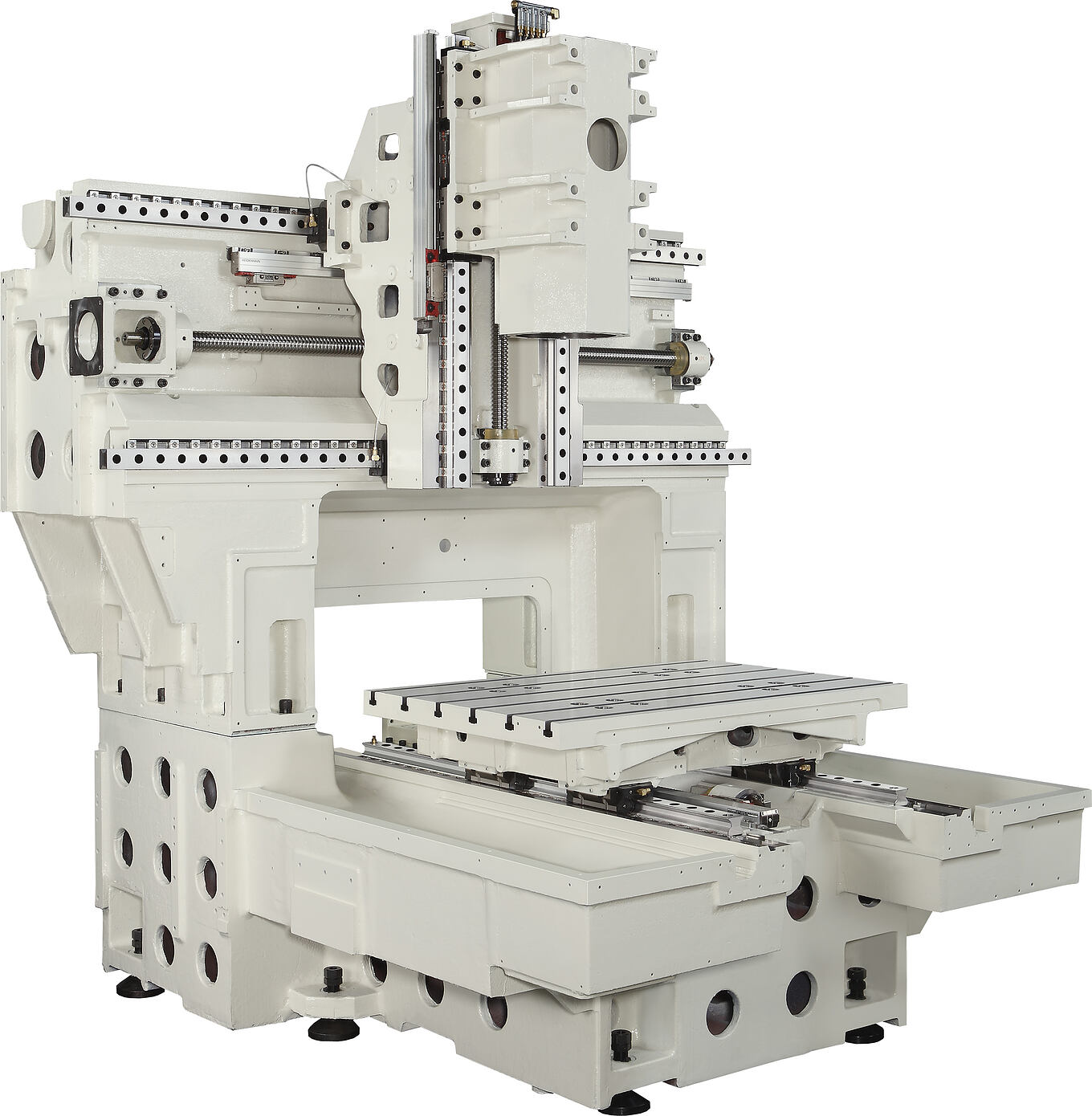

The stable and rigid portal design ensures high torsional rigidity on all axes. The automatic compensation of temperature fluctuations enables machining with long running times and, moreover, high precision. With the 3-axis gantry machining centers, CNC machining of large workpieces with high component weights as well as small part machining of micro molds is possible. In all cases, the quality of the surfaces is very high due to the mechanical accuracy and temperature resistance of the machining centers.

CNC-Maschines

3-axis

high precision

Discover the complete range of high rigidity 3-axis machining centers

X-Axis (mm)

600

Y-Axis (mm)

600

Z-Axis (mm)

350

Table working surface W x D (mm)

600 x 600

Spindle Speed (rpm)

36.000

X-Axis (mm)

1.020

Y-Axis (mm)

700

Z-Axis (mm)

500

Table working surface W x D (mm)

1.050 x 700

Spindle Speed (rpm)

15.000

_.png)

X-Axis (mm)

1.250

Y-Axis (mm)

950

Z-Axis (mm)

580

Table working surface W x D (mm)

1.360 x 960

Spindle Speed (rpm)

15.000

X-Axis (mm)

1.600

Y-Axis (mm)

1.300

Z-Axis (mm)

700

Table working surface W x D (mm)

1.900 x 1.300

Spindle Speed (rpm)

15.000

X-Axis (mm)

2.200

Y-Axis (mm)

1.600

Z-Axis (mm)

800

Table working surface W x D (mm)

2.400 x 1.600

Spindle Speed (rpm)

15.000

X-Axis (mm)

2.200

Y-Axis (mm)

2.200

Z-Axis (mm)

800

Table working surface W x D (mm)

2.400 x 2.100

Spindle Speed (rpm)

15.000

X-Axis (mm)

3.200

Y-Axis (mm)

1.600

Z-Axis (mm)

800

Table working surface W x D (mm)

3.320 x 1.600

Spindle Speed (rpm)

15.000

X-Axis (mm)

3.200

Y-Axis (mm)

2.200

Z-Axis (mm)

800

Table working surface W x D (mm)

3.320 x 2.100

Spindle Speed (rpm)

15.000

X-Axis (mm)

4.200

Y-Axis (mm)

1.600

Z-Axis (mm)

800

Table working surface W x D (mm)

4.240 x 1.600

Spindle Speed (rpm)

15.000

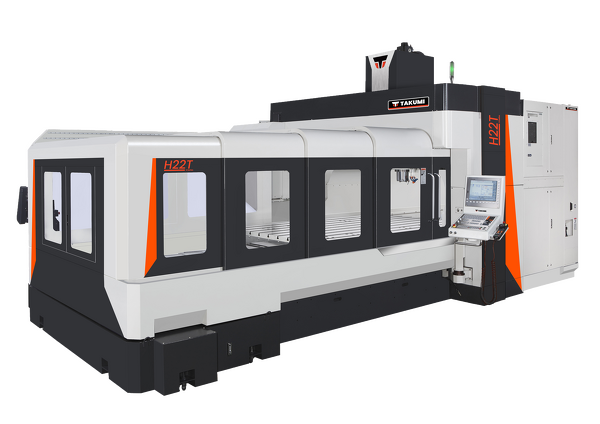

High dynamics for maximum performance

The H-series machining centers stand for first-class performance in highly dynamic applications in tool and die making, both in terms of surface quality and consistent precision. The versatile CNC machines achieve optimum results for any size of component - from machining small parts such as micro molds to large and particularly heavy components. In the process, high mechanical accuracy, low-vibration machining, and thermal stability, even over long runtimes, ensure surfaces whose quality meets the highest standards down to the last detail - without the need for time-consuming post-processing.

Experience the highlights of the H-Series

The H-series machining centers stand for first-class performance in highly dynamic applications in tool and die making, both in terms of surface quality and consistent precision. The versatile CNC machines achieve optimum results for any size of component - from machining small parts such as micro molds to large and particularly heavy components. In the process, high mechanical accuracy, low-vibration machining, and thermal stability, even over long runtimes, ensure surfaces whose quality meets the highest standards down to the last detail - without the need for time-consuming post-processing.

Portal milling machines with hand tested quality

At TAKUMI, we place great emphasis on ensuring that each of our CNC machining centers is manufactured to the highest quality, down to the last detail, and is therefore built to last. That's why the contact surfaces of the linear guides and machine components are scraped by hand - for the maximum possible in expertly tested precision.

Ergonomic high-end machines for your production

TAKUMI's 3-axis gantry machining centers feature generously sized cab windows for ideal control. Ergonomic operation and loading are facilitated by extra-wide opening doors for loading and unloading the milling machines. The swivel-mounted control unit allows optimum access to the work area with maximum operating comfort.

The user-friendly application is completed by the fact that all H-series machining centers are equipped with the latest version of the Heidenhain TNC 640 control. The control software with numerical - or optionally dialog-based - programming is a highly flexible tool for custom-fit production and implementation of customer-specific requirements.

The user-friendly application is completed by the fact that all H-series machining centers are equipped with the latest version of the Heidenhain TNC 640 control. The control software with numerical - or optionally dialog-based - programming is a highly flexible tool for custom-fit production and implementation of customer-specific requirements.

We are happy to be there for you.

You would like to learn more about the technical data of our machining centers or you are looking for support for a product comparison or the selection of the suitable TAKUMI machine tool? Use our contact form or send us an email or use our service hotline!

Discover our CNC high performance machining centers

3-axis verticalV-Series

5-axis preciseU-Series

GraphiteG-Series