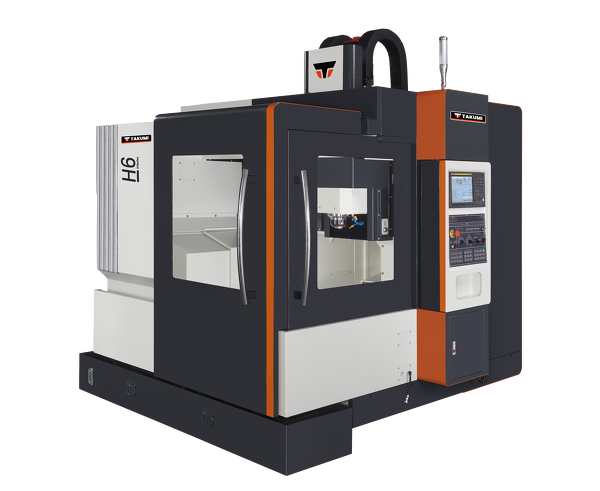

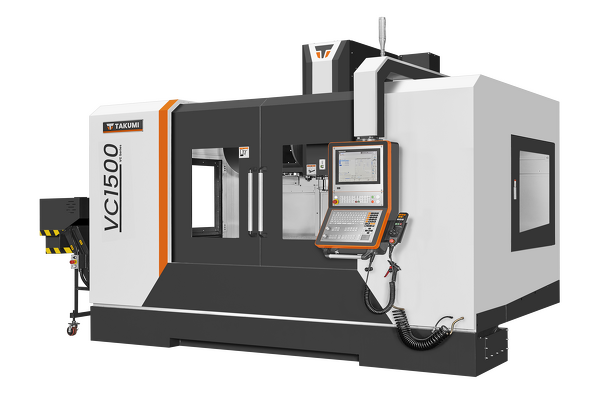

TAKUMI's V-series combine versatility with the highest precision and performance. The vertical machining centers are high-performance CNC machine tools with a focus on vertical machining of mechanical engineering parts and the production of workpieces for tool and mold making. Our vertical 3-axis machining centers are equipped with the clear and user-friendly Heidenhain TNC 640 control. The 3-axis milling machines with cross table can optionally be equipped with an NC rotary table for CNC part production with 4 axes or optionally even 5 axes.

CNC-Maschines

3-axis

vertical

Discover the complete range of vertical 3-axis machining centers

X-Axis (mm)

1.200

Y-Axis (mm)

660

Z-Axis (mm)

610

Table working surface W x D (mm)

1.250 x 650

Spindle Speed (rpm)

12.000

X-Axis (mm)

1.524

Y-Axis (mm)

762

Z-Axis (mm)

720

Table working surface W x D (mm)

1.600 x 760

Spindle Speed (rpm)

8.000

X-Axis (mm)

1.800

Y-Axis (mm)

850

Z-Axis (mm)

750

Table working surface W x D (mm)

1.900 x 850

Spindle Speed (rpm)

8.000

X-Axis (mm)

860

Y-Axis (mm)

520

Z-Axis (mm)

610

Table working surface W x D (mm)

1.000 x 520

Spindle Speed (rpm)

15.000

X-Axis (mm)

1.060

Y-Axis (mm)

520

Z-Axis (mm)

610

Table working surface W x D (mm)

1.160 x 520

Spindle Speed (rpm)

15.000

X-Axis (mm)

1.067

Y-Axis (mm)

610

Z-Axis (mm)

610

Table working surface W x D (mm)

1.270 x 610

Spindle Speed (rpm)

15.000

Cross table machining centers with many facets

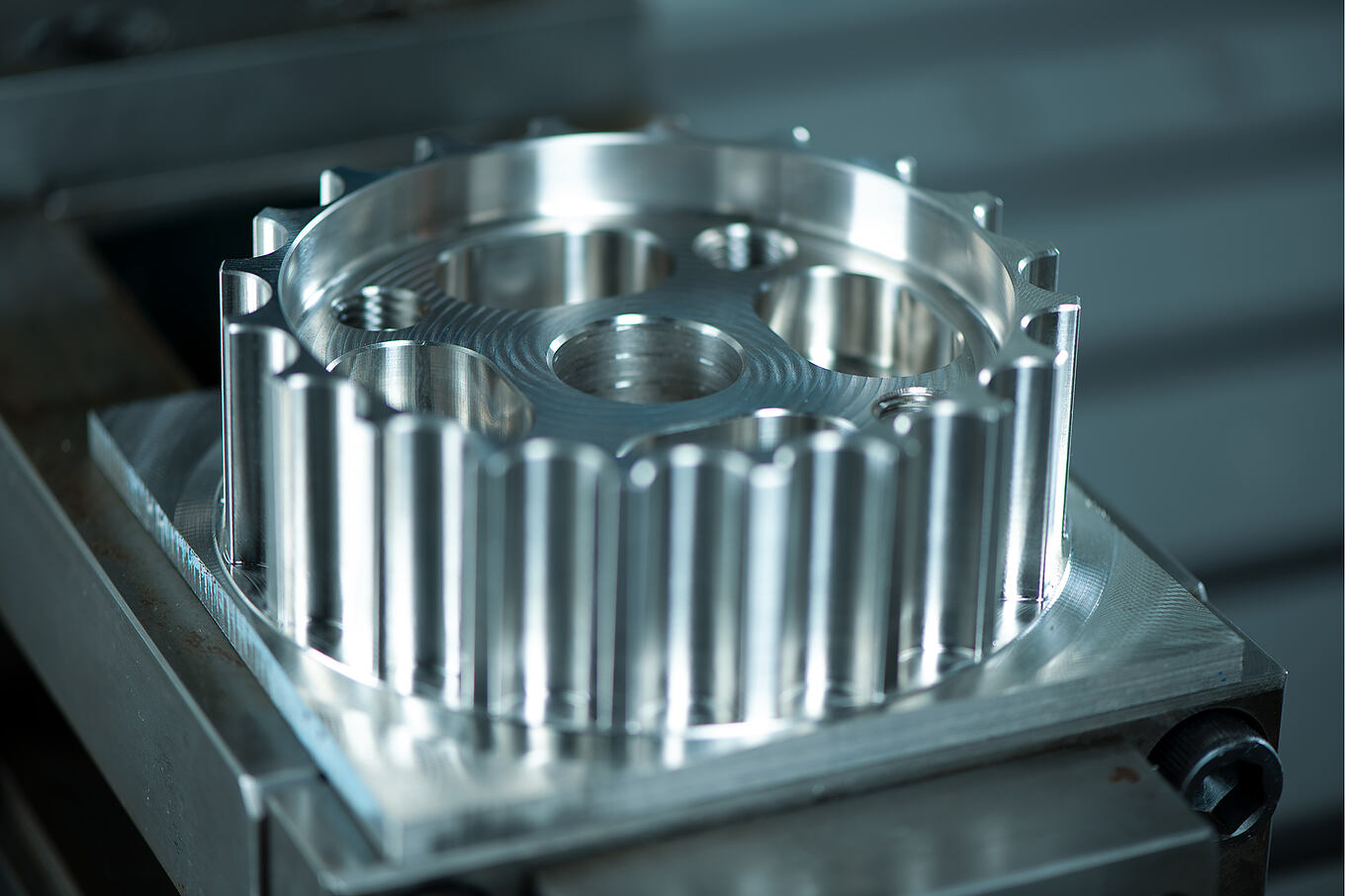

The V-Series 3-axis vertical machining centers are versatile, high-performance machines that perform any task, no matter how demanding, with the utmost accuracy - for example, roughing solid steel molds. With their robust design and solid construction, our V-Series machines are the ideal choice for high-performance machining of machine, tool and die components - developed by visionaries and made for a wide range of manufacturing requirements.

Experience the highlights of the V-series

- Perfect balance between high cutting performance and maximum stability

- Highly rigid machine structure with robust cast components machined for precision

- Symmetrical and box-shaped machine bed made of monolithic cast iron

- Hand-scraped contact surfaces and flat guides to increase accuracy

- Preloaded ball screws for minimized thermal growth

- Spindle cooling for optimum heat dissipation

- Synchronized direct drives for increased precision and reduced stress in the microstructure

- Integrated chip flushing and removal system

- Optional: absolute direct path measuring systems for fast machine start-up

- Easy and ergonomic loading and unloading due to wide opening machine doors

- Swiveling control panel for optimized space requirements and more operator comfort

- User-friendly Heidenhain TNC640 control system

- Fast service response times and high spare parts availability

3-axis CNC machining centers for every workshop need

The CNC milling machines of the V-series are favorable models for a cost-optimized investment. Due to the compact design, the vertical machining centers have only a small space requirement and are thus optimally suited for workshop operation and workshop programming. The cross table machines are available in all common table sizes.

Thanks to numerous additional options, our TAKUMI vertical machining centers can be individually configured - in addition to the optional rotary table, these include, for example, a touch probe system for measuring workpieces and tools, a scraper belt conveyor instead of a slat-band conveyor, a bypass filter system and much more. Feel free to contact us for the customization of your machining center.

Thanks to numerous additional options, our TAKUMI vertical machining centers can be individually configured - in addition to the optional rotary table, these include, for example, a touch probe system for measuring workpieces and tools, a scraper belt conveyor instead of a slat-band conveyor, a bypass filter system and much more. Feel free to contact us for the customization of your machining center.

We are here for you.

You would like to learn more about the technical data of our machining centers or are looking for support for a product comparison or the selection of the suitable TAKUMI machine tool? Use our contact form, send us an email or use our service hotline!

Discover our CNC high performance machining centers

3-axis high precisionH-Series

5-axis preciseU-Series

GraphiteG-Series