Our TAKUMI Machining Centers are equipped with the latest Heidenhain TNC control. 640.

CNC-Maschines3-axis vertical, V-Series

Compact high performers

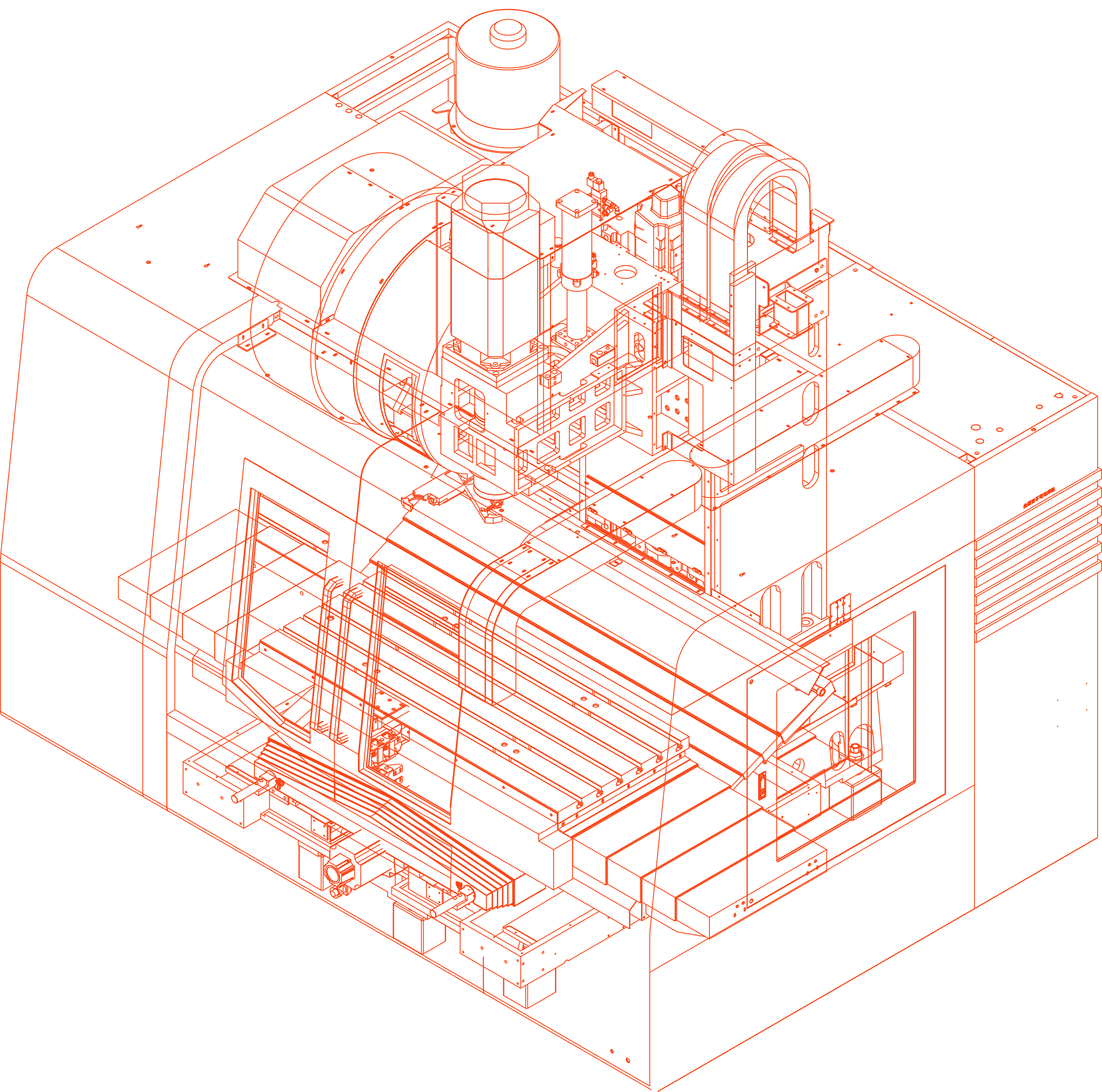

TAKUMI V 12

Solid and precise at the same time - that's the TAKUMI V 12 for vertical machining of medium-sized components in tool, mold and machine construction. The compact machine tool, which has a table clamping area of 1,250 x 650 mm, a maximum table load of 1,200 kg and a 24-position tool changer with double gripper, is also suitable for roughing and pre-roughing operations.

Travels and Table

X-Axis (mm): 1.200

Y-Axis (mm): 660

Z-Axis (mm): 610

Table working surface W x D (mm): 1.250 x 650

Spindle Speed (rpm): 12.000

Produkt anfragen

Y-Axis (mm): 660

Z-Axis (mm): 610

Table working surface W x D (mm): 1.250 x 650

Spindle Speed (rpm): 12.000

- Belt-driven spindle or gear-driven spindle up to 12,000 rpm

- Pretensioned ballscrews for all axes to prevent thermal deformation

- Spindle cooler

- User-friendly, ergonomic access for loading

- Optional: Gear-driven spindle torque up to 640 Nm (S1)

Details

Specifications - V 12

| Travels | |

|---|---|

| X-Axis (mm) | 1.200 |

| Y-Axis (mm) | 660 |

| Z-Axis (mm) | 610 |

| Table | |

|---|---|

| Table working surface W x D (mm) | 1.250 x 650 |

| Load max. (uniform distribution) (kg) | 1.200 |

| Distance from spindle nose to table (mm) | 150 - 760 |

| T-Slots (DIN 650) | 5 x 18mm x 100mm |

| Spindle | |

|---|---|

| Spindle Taper | SK40 / BT40 |

| Type | Riemen |

| Power S1/S6 (kW) | 10 / 14 |

| Torque S1/S6 (Nm) | 63,7 / 89 |

| Spindle Speed (rpm) | 12.000 |

| Feed Rate | |

|---|---|

| Rapid Traverse X/Y/Z-Axis (m/min) | 24 / 24 / 20 |

| Cutting Feed Rate X/Y/Z-Axis (mm/min) | 8 |

| ATC & Magazine | |

|---|---|

| ATC Type | Doppelgreifer |

| Magazine Capacity | 24 |

| Maximum Tool Diameter (mm) full / next pocket empty | 80 |

| With Empty Pockets (mm) | 150 |

| Maximum Tool Length (mm) | 300 |

| Maximum Tool Weight (kg) | 7 |

| Space & System Requirements | |

|---|---|

| Maximum Floor Space (mm) W x L x H | 5.418 x 3.786 x 3.092 |

| Machine Net Weight (kg) | 8.100 |

| Electrical Power Consumption (kVA / A) | 35 / 70 |

| Air Requirements (bar) | 6 |

Spindle

Choose the spindle that suits you

| Spindle options | V 12 | |

|---|---|---|

| Drehzahl max. (1/min) | 12.000 | 6.000 |

| Leistung S1/S6 (kW) | 10 / 14 | 10 / 14 |

| Drehmoment S1/S6 (Nm) | 63,7 / 89 | 360 / 503 |

| Schnittstelle | SK40BigPlus | SK50 |

| Standard / Optional | Standard | Optional |

Features

Always perfectly equipped

Great features of our standard equipment

- Heidenhain Control TNC 640

- Belt drive spindle 12.000 1 /min. SK40BigPlus

- Coolant wash-down system

- Spindle chiller

- Full enclosure

- Programmable airblow machining

- Oil Skimmer

- Wash-down gun and air gun

- Chip conveyor and cart

- Manual pulse generator (MPG)

- Ethernet interface

With further optional equipment you can adapt the TAKUMI V 12 to your needs

- Coolant through spindle (CTS 30 bar)

- Rotary table (4th / 5th axis)

- Part probe measurement system

- Tool probe measurement system

- Programmable airblow through spindle machining

- Oil mist device

- Oil mist collector

- Scraper type conveyor instead of chain type conveyor

- Production package Knoll

- Bypass Filter

- Rotoclear

Highlights

Heidenhain Control TNC 640

Precise High performance spindle

With the V-series, TAKUMI offers the optimal spindle for your demands

- Spindle speeds 12.000 (rpm)

- Output up to 10 kW – 25 kW

- Interface: SK 40 BigPlus / BT40 / SK50

Extremely stiff and high-presision mechanical structure

The load-bearing mechanical structures such as bed, pillar, bed sledge are made of heat-treated and stress-released Meehanite cast iron. The thereby gained absorption capacity enables low-vibration machining processes. This ensures high surface quality on the workpiece and increases the tool life.