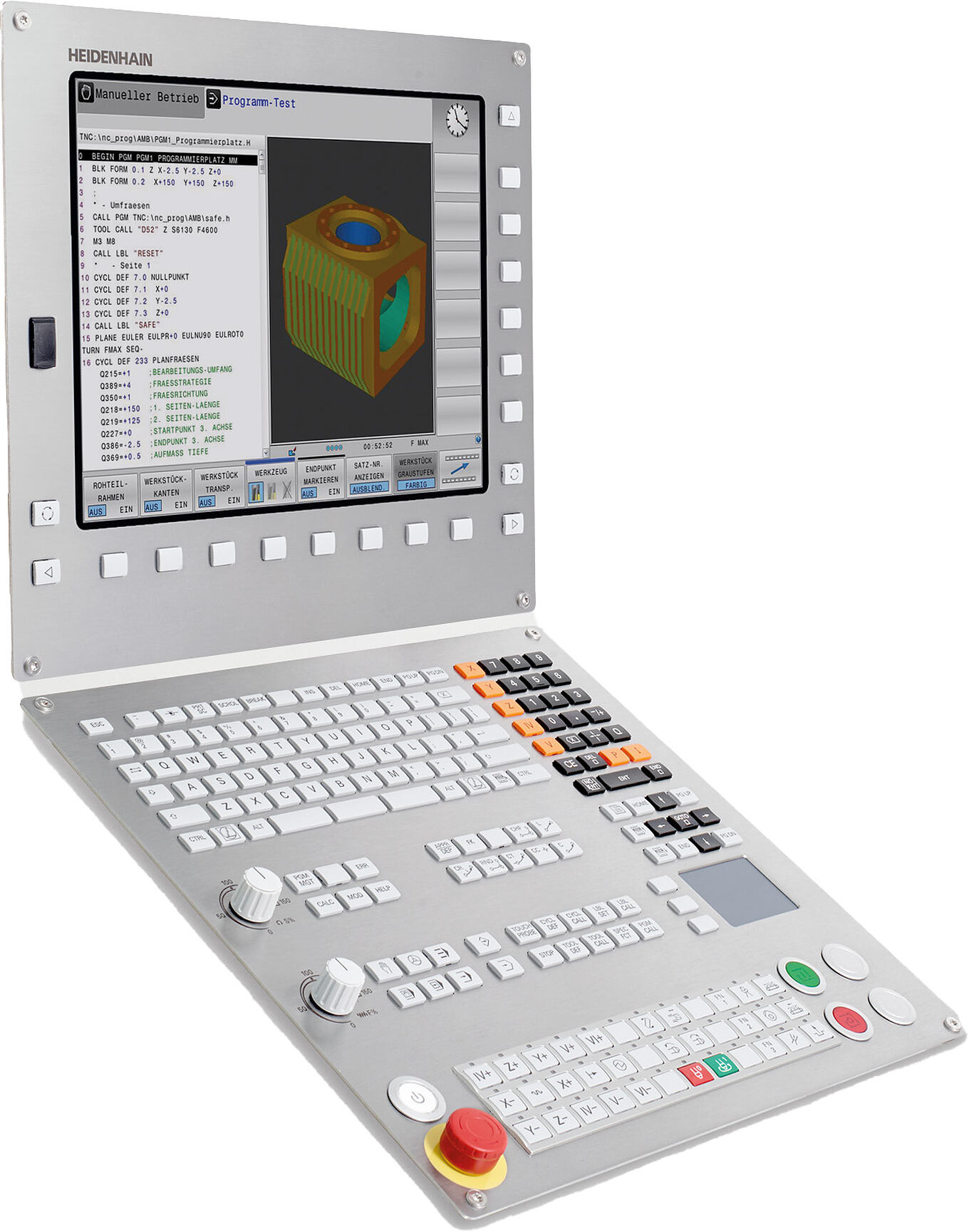

Our TAKUMI Machining Centers are equipped with the latest Heidenhain TNC control 640.

CNC-MaschinesGraphite, G-Series

The graphite artist

TAKUMI G 1000

The G 1000 is the ideal CNC machine for your production if you are looking for a steadfast solution for graphite machining with an optimal price-performance ratio. The machining center is equipped with first-class components as standard and can also be expanded with numerous additional options - for the production of workpieces with the finest contours specifically according to the requirements of your production.

Travels and Table

X-Axis (mm): 1.020

Y-Axis (mm): 700

Z-Axis (mm): 500

Table working surface W x D (mm): 1.050 x 700

Spindle Speed (rpm): 25.000

Produkt anfragen

Y-Axis (mm): 700

Z-Axis (mm): 500

Table working surface W x D (mm): 1.050 x 700

Spindle Speed (rpm): 25.000

- Completely enclosed machining area incl. extraction for modern graphite machining.

- High form and dimensional accuracy due to compact gantry design

- Comprehensive basic equipment for a first-class price/performance ratio

- Stable and rigid gantry construction with high temperature resistance

- Absolute direct travel measuring system

- System for compensation of thermal spindle expansion

- Cooling system for the ball screw - 25,000 min-1, HSK-E50, motor spindle Graphite extraction system"

Details

Specifications - G 1000

| Travels | |

|---|---|

| X-Axis (mm) | 1.020 |

| Y-Axis (mm) | 700 |

| Z-Axis (mm) | 500 |

| Table | |

|---|---|

| Table working surface W x D (mm) | 1.050 x 700 |

| Load max. (uniform distribution) (kg) | 800 |

| Distance from spindle nose to table (mm) | 180 - 680 |

| Distance between columns (mm) | 1.080 |

| T-Slots (DIN 650) | 6 x 18 x 125 |

| Spindle | |

|---|---|

| Spindle Taper | HSK50-E |

| Type | Motorspindel |

| Power S1/S6 (kW) | 20 / 26 |

| Torque S1/S6 (Nm) | 10,4 / 13,5 |

| Spindle Speed (rpm) | 25.000 |

| Feed Rate | |

|---|---|

| Rapid Traverse X/Y/Z-Axis (m/min) | 30 / 30 / 30 |

| Cutting Feed Rate X/Y/Z-Axis (mm/min) | 20 |

| ATC & Magazine | |

|---|---|

| ATC Type | Doppelgreifer |

| Magazine Capacity | 30 |

| Maximum Tool Diameter (mm) full / next pocket empty | 75 |

| With Empty Pockets (mm) | 120 |

| Maximum Tool Length (mm) | 300 |

| Maximum Tool Weight (kg) | 7 |

| Space & System Requirements | |

|---|---|

| Maximum Floor Space (mm) W x L x H | 3.950 x 4.600 x 2.950 |

| Machine Net Weight (kg) | 9.100 |

| Electrical Power Consumption (kVA / A) | 50 / 125 |

| Air Requirements (bar) | 6 |

Spindle

Choose the spindle that suits you

| Spindle options | G 1000 |

|---|---|

| Drehzahl max. (1/min) | 25.000 |

| Leistung S1/S6 (kW) | 20 / 26 |

| Drehmoment S1/S6 (Nm) | 10,4 / 13,5 |

| Schnittstelle | HSK50-E |

| Standard / Optional | Standard |

Features

Always perfectly equipped

Great features of our standard equipment

- Heidenhain iTNC 640 Control

- Graphite collector

- Linear Scales

- 15,000 RPM, CAT/BT40, inline spindle

- Spindle thermal compensation system

- Chip flushing

- Spindle cooling

- Full enclosure

- Ethernet interface

- 30T arm type ATC (G1000)

With further optional equipment you can adapt the TAKUMI G 1000 to your needs

- Ballscrew cooling system

- Part probe measurement system

- Touch probe for tool measurement

- Manual pulse generator (MPG)

- Programmable airblow machining

- Programmable airblow through spindle machining

Highlights

Heidenhain Control TNC 640

Extraction unit

- Fully-enclosed covers make sure a safe, clean and healthy working environment and effectively reduce graphite particles contamination to its minimum.

Vaccum system on the headstock

- The particle-collection nozzle keeps a distance at 150mm to the tool tip which not only makes the particle-collection rate above 83%,but also avoids from the motion conflict.