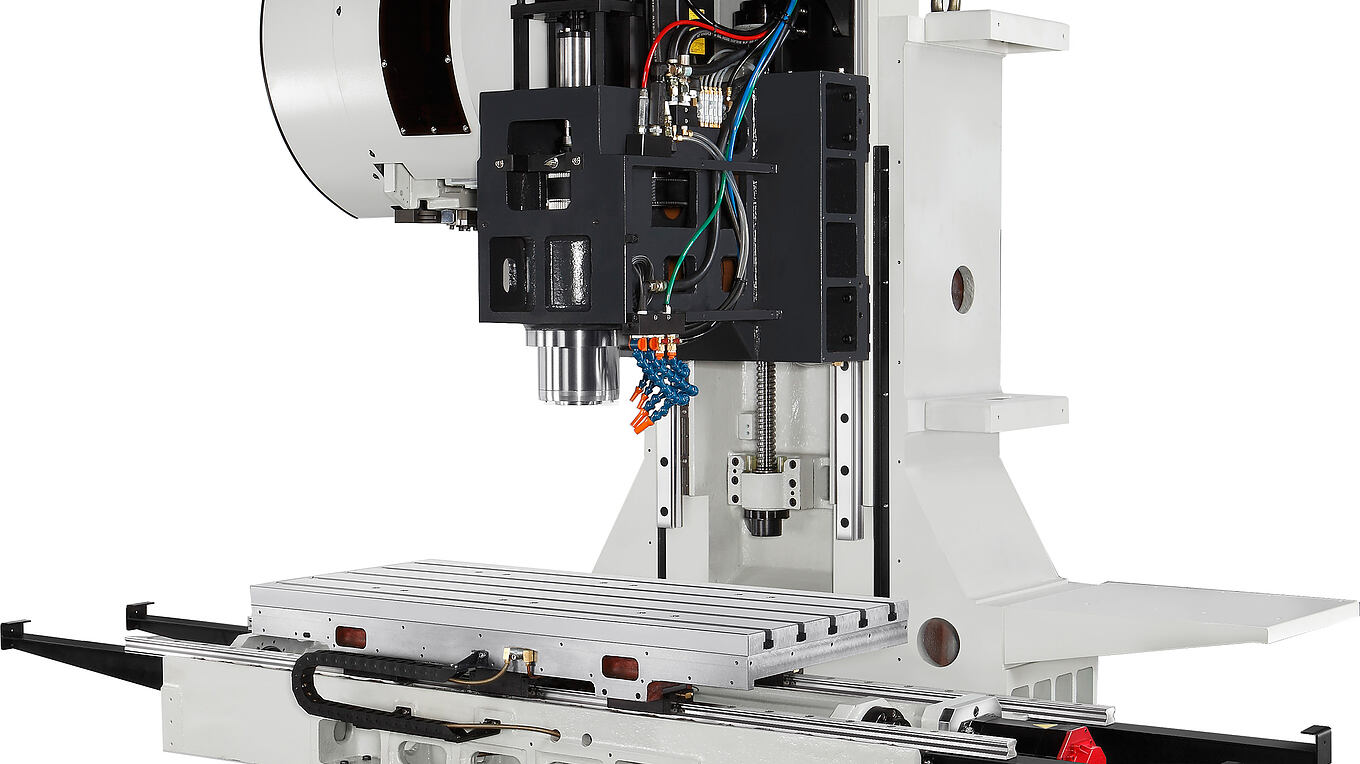

Over a period extending through more than half a year, and month for month, TAKUMI delivered bridge-type machining centers to an address in Eibiswald, just south of Graz, Austria: for a total of two "H7" models and no less than eight "H10" Series machines. This investment by Fuchshofer Präzisionstechnik was their response to some very specific customer requirements, of the kind that so often lend impetus to this company's actions and acquisitions. Owner Hannes Fuchshofer: "These ten TAKUMIs offer us the ideal means for satisfying these demands."

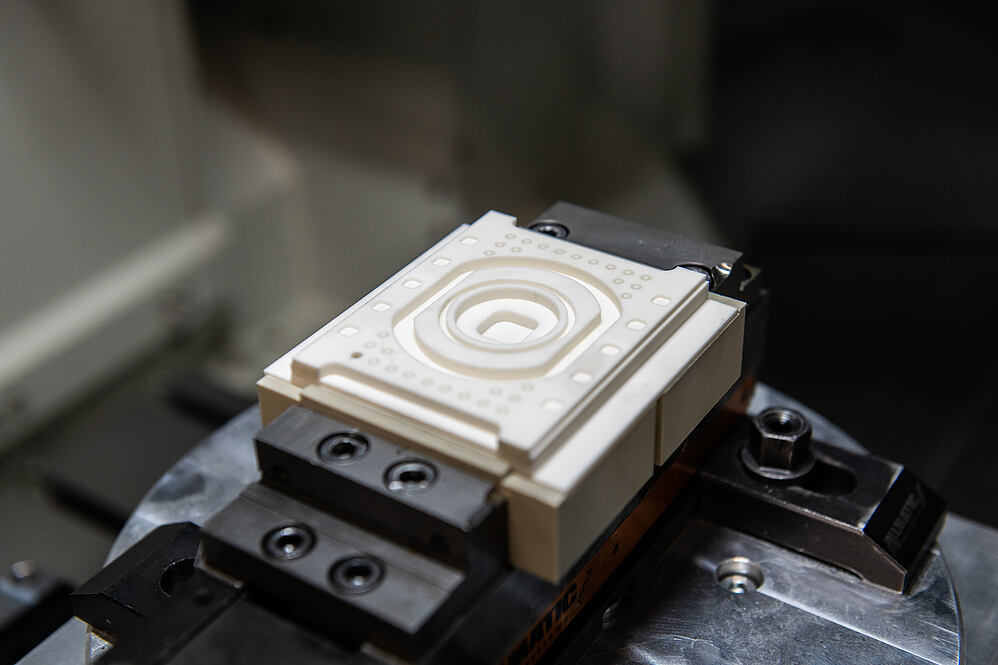

The assignment in question is to produce equipment, molds and dies for manufacturing machine components destined for use in the semiconductor industry. "This means that we are machining hard and extremely brittle composite materials such as quartz glass, along with fiber-based and other special materials. It's a challenging mix, and there are additional variations from one part to the next," reports Fuchshofer. "Nevertheless, precision is essential, and we also have to keep the thermal stresses as low as possible." With part dimensions of 500 x 500 mm, the tolerances that have to be maintained for elements such as mounting surfaces and assembly clearances are measured in hundredths of a millimeter. In view of the fact that the company's customer base stems primarily from the semiconductor, automotive and aerospace sectors, this is a thoroughly typical assignment for Fuchshofer. These specialists hailing from Austria's Steiermark region have been machining an extensive array of materials for almost thirty years. "We always strive to transfer this expertise to machines representing a variety of design configurations," emphasizes the company owner. "That's what made the TAKUMIs so attractive for us."

Never stand still

The focus at Fuchshofer Präzisionstechnik is fixed on milling, lathe-turning and machining precision components. At the same time, the enterprise's offerings also embrace development and construction of special-purpose machines, as well as construction of complete component assemblies. 2005 marked the arrival of ultrasonic technology in Eibiswald, allowing the processing spectrum to expand to include sensitive materials such as quartz glass and ceramics. Then 2015 witnessed the advent of additive manufacture, which joined ultrasonic machining, CNC processing and machine-tool manufacture to form the fourth pillar of this precision manufacturer's activities.

The company's debut consisted of Fuchshofer, then in his mid-twenties, running what he likes to call a "one man show": quite literally a garage-based enterprise – a tractor and automotive garage that he took over from his father. What happened next was a genuine success story: an expanding circle of customers, new buildings and annexes added on a regular basis, and strategic extension embracing manufacturing technology accompanied by steady acquisition of additional employees. "The consistent cornerstone of my approach was flexible production, and it was all based on high levels of technical competence from the employees," underscores the business owner. His team now counts more than one hundred associates. Also available in Eibiswald are apprenticeships leading to certification in mechatronics and machining. Not the least of the achievements stems from the CoViD period, when the "Fuchshofer Academy" was established with a program of promoting more intensive training and advanced instruction. "Never stand still, always be on the lookout for new experiences and expertise," is the core principle that inspires this pacesetter. "That is how we evolved into what we are now: with impressive technical resources, highly flexible, and in a very good strategic position."

"Right from the start, it was no problem to deliver and set up ten machines in seven months. And then when it's possible to set up and install a delivered machine within a single day, that's a neat proposition."

"Right from the start, it was no problem to deliver and set up ten machines in seven months. And then when it's possible to set up and install a delivered machine within a single day, that's a neat proposition."