CNC-Maschines3-axis high precision, H-Series

The custom solution for your application

_.png.1536.webp)

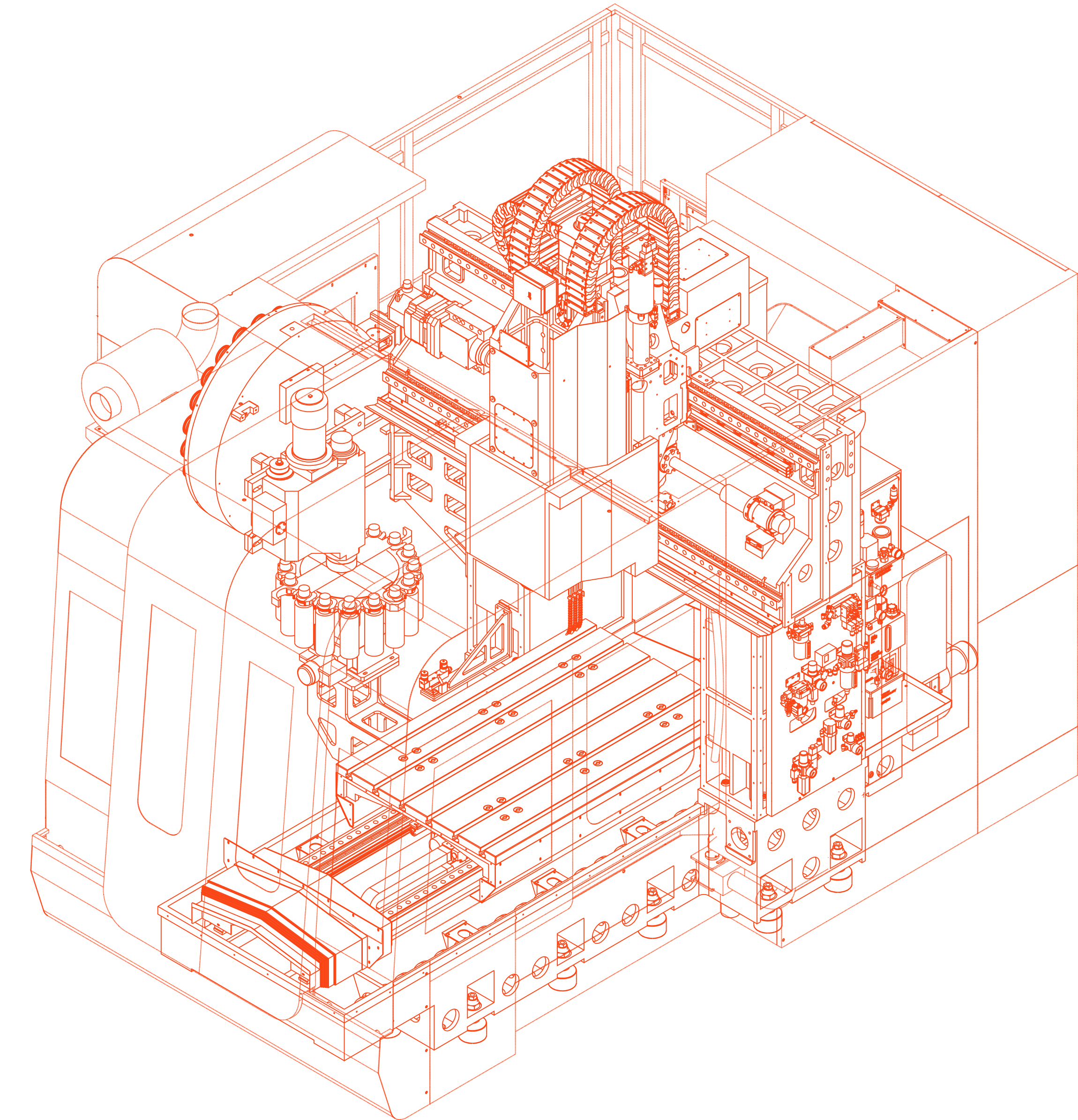

TAKUMI H 12 E

The H 12 E machining center combines stable performance with precise dynamics. With a table clamping area of 1,360 x 960 mm, it is the ideal choice for space-saving CNC machining of medium-sized workpieces and highly dynamic applications in tool and mold making. As standard, the portal machining center already comes with everything you need for precise milling. In addition, you can optimally adapt the machine to your requirements with individual configuration options.

Travels and Table

X-Axis (mm): 1.250

Y-Axis (mm): 950

Z-Axis (mm): 580

Table working surface W x D (mm): 1.360 x 960

Spindle Speed (rpm): 15.000

Produkt anfragen

Y-Axis (mm): 950

Z-Axis (mm): 580

Table working surface W x D (mm): 1.360 x 960

Spindle Speed (rpm): 15.000

- Ideal for crane loading

- High rigidity and dynamic response for perfect milling results

- User-friendly, ergonomic access for loading

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle chiller

Details

Specifications - H 12 E

| Travels | |

|---|---|

| X-Axis (mm) | 1.250 |

| Y-Axis (mm) | 950 |

| Z-Axis (mm) | 580 |

| Table | |

|---|---|

| Table working surface W x D (mm) | 1.360 x 960 |

| Load max. (uniform distribution) (kg) | 2.000 |

| Distance from spindle nose to table (mm) | 200 - 780 |

| Distance between columns (mm) | 1.060 |

| T-Slots (DIN 650) | 6 x 22 x 160 |

| Spindle | |

|---|---|

| Spindle Taper | HSK63-A / SK40 - BigPlus / BBT40 |

| Type | In-Line |

| Power S1/S6 (kW) | 10 / 14 |

| Torque S1/S6 (Nm) | 63,7 / 89,4 |

| Spindle Speed (rpm) | 15.000 |

| Feed Rate | |

|---|---|

| Rapid Traverse X/Y/Z-Axis (m/min) | 30 / 30 / 30 |

| Cutting Feed Rate X/Y/Z-Axis (mm/min) | 20 |

| ATC & Magazine | |

|---|---|

| ATC Type | Doppelgreifer |

| Magazine Capacity | 30 |

| Maximum Tool Diameter (mm) full / next pocket empty | 75 |

| With Empty Pockets (mm) | 120 |

| Maximum Tool Length (mm) | 300 |

| Maximum Tool Weight (kg) | 7 |

| Space & System Requirements | |

|---|---|

| Maximum Floor Space (mm) W x L x H | 4.730 x 4.288 x 3.150 |

| Machine Net Weight (kg) | 9.810 |

| Electrical Power Consumption (kVA / A) | 60 / 87 |

| Air Requirements (bar) | 6 |

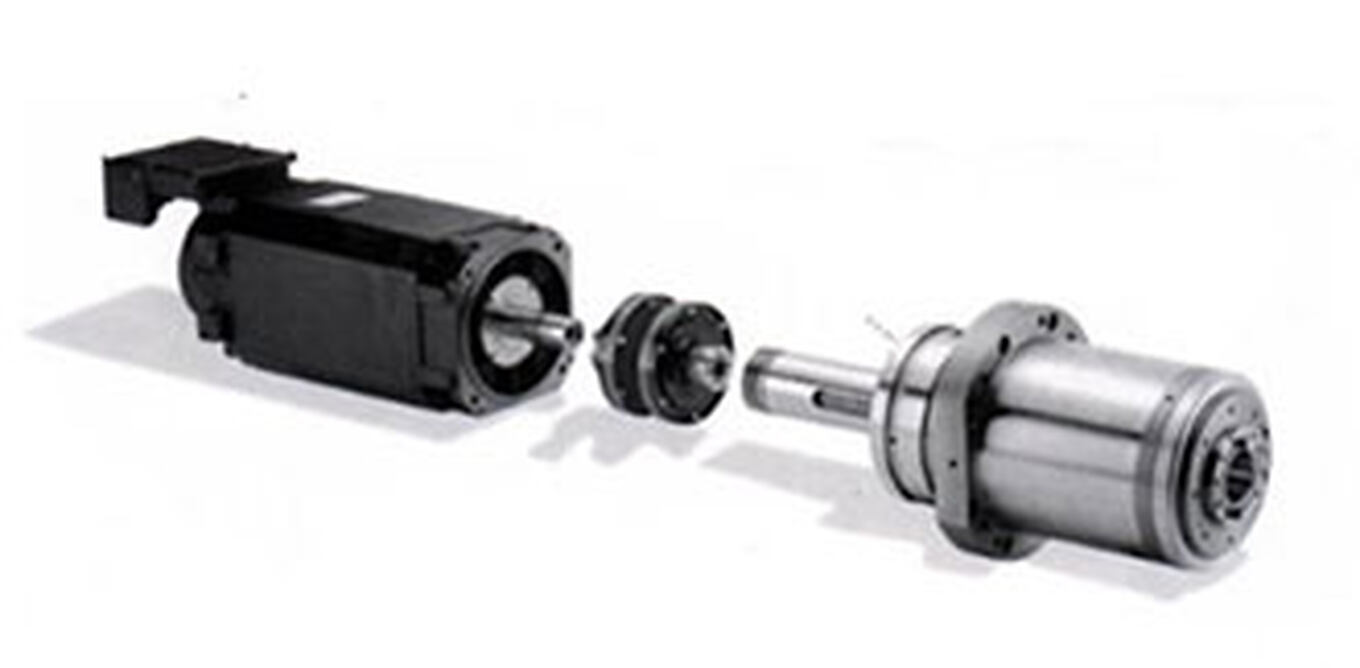

Spindle

Choose the spindle that suits you

| Spindle options | H 12 E | |||||

|---|---|---|---|---|---|---|

| Drehzahl max. (1/min) | 15.000 | 15.000 | 15.000 | 20.000 | 24.000 | 36.000 |

| Leistung S1/S6 (kW) | 10 / 14 | 10 / 14 | 20 / 34 | 25 / 35 | 30 / 45 | 20 / 26 |

| Drehmoment S1/S6 (Nm) | 63,7 / 89,4 | 63,7 / 89,4 | 82 / 139,6 | 83,2 / 116,5 | 29 / 43,5 | 10,4 / 13,5 |

| Schnittstelle | SK40BigPlus | BBT40 / HSK 63 A | SK40BigPlus / BBT40 / HSK63-A | HSK 63 A | HSK 63 A | HSK 50 E |

| Standard / Optional | Standard | Optional | Optional | Optional | Optional | Optional |

Features

Always perfectly equipped

Great features of our standard equipment

- Heidenhain control TNC 7

- Spindle thermal compensation system

- Chip flushing

- Spindle cooling

- Full enclosure

- Programmable airblow machining

- Oil mist device

- Wash down gun and air gun

- Chip conveyor and cart

- Ethernet interface

- 15,000 rpm, inline spindle

- Coolant through spindle (CTS 30bar)

- Electronic handwheel

- Absolute direct path measuring systems

With further optional equipment you can adapt the TAKUMI H 12 E to your needs

- Rotary table (4th/5th axis)

- Touch probe for tool measurement

- Part probe measurement system

- Oil mist separator

- Hinge belt conveyor instead of scraper belt conveyor

- Scraper type conveyor

- Producation package Knoll

- Bypass Filter

- Rotoclear

- Ballscrew cooling system

- Programmable cooling air through the spindle

- Internal coolant supply through the spindle (IKZ 70 bar)

- Automatic doors

Highlights

Heidenhain control TNC 7

The TAKUMI H series portal machining centers are equipped with the latest version of the Heidenhain TNC 7 control as standard. Only the H 6 model is supplied with the TNC 7 basic version.

Precise High performance spindle

With the H series, TAKUMI offers the ideal spindle for your requirements

- Speeds from 12,000 to max. 42,000 (rpm)

- Power up to 10 kW – 45 kW

- Interfaces: HSK 40 E / HSK 50 E / HSK 63 A / HSK 100 A / SK40 - BigPlus / SK50 - BigPlus / BBT40 / BBT50

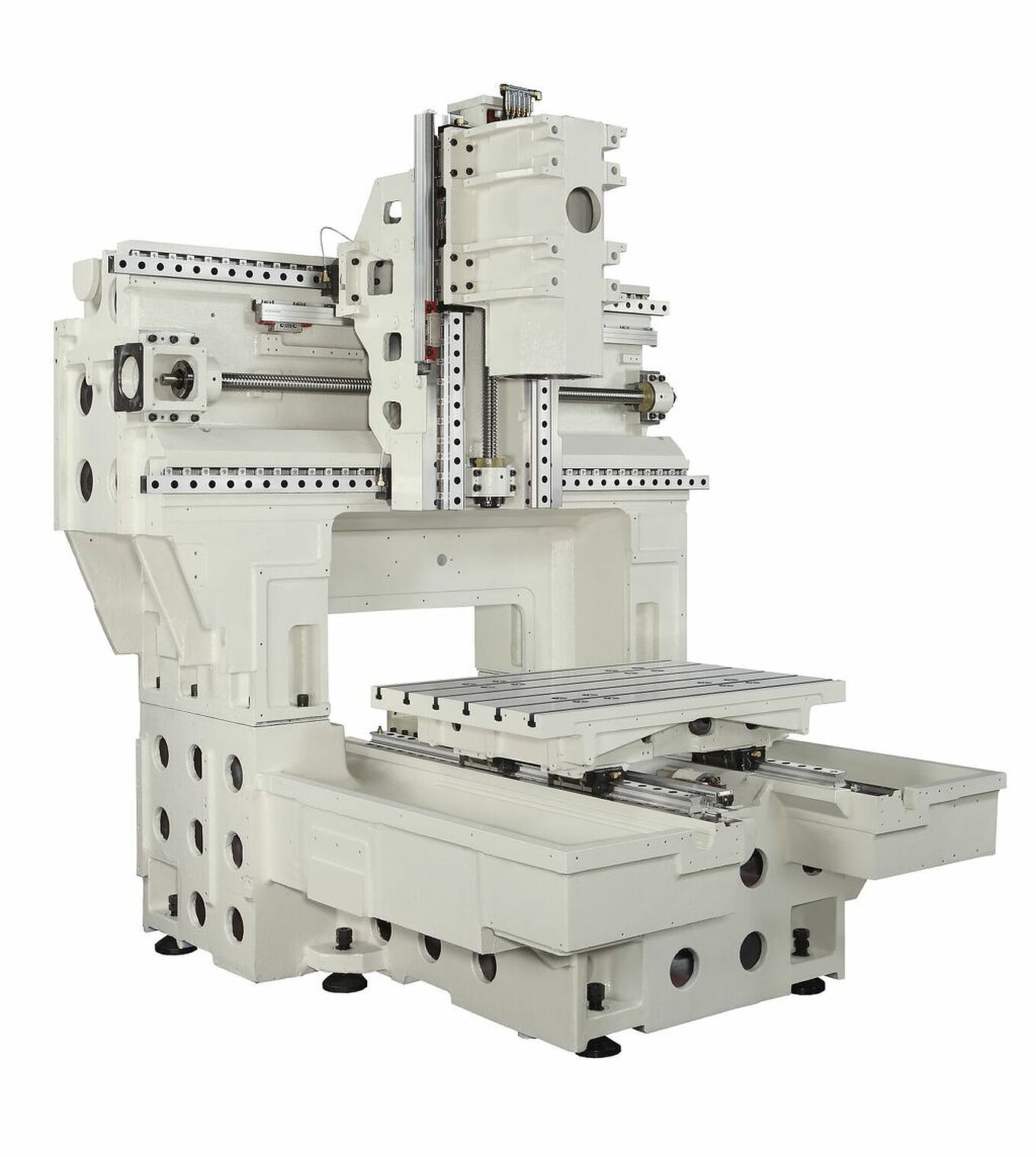

Extremely rigid and high-precision mechanical structure

- The load-bearing mechanical structures such as the bed, column, and bed slide are made of heat-treated Meehanite cast iron without residual stresses.

- The resulting absorption capacity enables low-vibration machining processes. This achieves the best possible quality on the workpiece surface and increases tool life.

Mechanical Accuracy

To increase the durability of wear parts, TAKUMI follows the philosophy of generating geometric accuracy directly from the machine’s mechanics.

During machine assembly, the highest level of effort is applied: for example, mounting surfaces are hand-scraped, components are aligned with maximum precision, and assembled with utmost care.

This reduces the need for subsequent compensation via the machine control system to an absolute minimum.

During machine assembly, the highest level of effort is applied: for example, mounting surfaces are hand-scraped, components are aligned with maximum precision, and assembled with utmost care.

This reduces the need for subsequent compensation via the machine control system to an absolute minimum.

Thermal Stability

The enemy of precision is thermal expansion. To eliminate this and provide you with highly accurate machining, TAKUMI equips its machines with the following features:

- Core-cooled and preloaded ball screws

- Thermal compensation for spindle expansion including sensors

- Liquid-cooled milling spindle

Reliable Results

To provide you with the ideal tool for high-precision machining, the following measures have been consistently implemented in the TAKUMI H-Series machining centers:

- Generously dimensioned, high-precision roller linear guides on all 3 axes

- Preloaded ball screws to absorb thermal deformation and maintain highest accuracy

- Six or more guide blocks for a balanced combination of dynamics and precision

Dynamics

All moving elements are designed with inherent stiffness.

The high-precision roller linear guides ensure fast response in acceleration and deceleration, enabling high dynamics. Due to the large contact surfaces, they also provide optimal load distribution across the guideways. The load-bearing capacity and torsional rigidity of each axis are maximized, reducing guideway wear and preventing vibration even under heavy cutting forces.

The optimal number and positioning of guide blocks further enhance stiffness and ensure consistent accuracy in long-term operation.

The optimal number and positioning of guide blocks further enhance stiffness and ensure consistent accuracy in long-term operation.

Loading

The loading access points of the TAKUMI H-Series are extremely generous. Whether loading large components via crane or performing quick changeovers for smaller parts, all processes run smoothly and without restrictions.

Ergonomics

Centralized maintenance units as well as easily accessible working and operator interfaces ensure smooth setup processes and efficient production workflows.

Chip Management

Measures such as:

- Strategically positioned coolant flushing systems

- Steeply inclined interior walls

- Hinge-type or optional scraper conveyors

- Wide-open chip drop openings

- Screw conveyors mounted on hardened guide surfaces (from H 16 onwards)

ensure that chip volume and heat are removed effectively and reliably.

Integrated Oil Skimmer

The oil skimmer prevents the coolant emulsion from deteriorating, even under fluctuating or high temperatures. This effectively increases the coolant’s service life.

Reasons for your Success with the TAKUMI H-Series

- TAKUMI has been a successful partner for industry and research for over 30 years

- Product development driven by customer and market requirements

- H-Series designed specifically for mold & die applications

- Service support through HURCO’s established service network

- Sales and customer support provided by the proven HURCO network

- Longevity ensured by oversized structural elements and premium components

- Accuracy through rigid gantry construction and targeted measures for thermal stability

- Process reliability for long machining cycles with surface finishes that require no reworking

- The right machine type for every component size